Woodfield Emergency Release Coupling (ERC) is designed & manufactured for safety of operators and environment in case of an emergency. ERC can be used with hoses or loading arms during transfer of product from terminal to tanker or vice-versa.

In case of an emergency if the tank truck has to move, ERC shall get activated and detach from the hose or loading arms safely with minimum spillage by instantly closing the safety valves in the ERC.

Shear Pin Type

(S-ERC)

Operation Philosophy

Non-axial forces are generated as the tanker moves in case of an emergency and these forces are transferred on the ERC spring plungers through a cable release coupling. With this the ERC gets separated with instant closing of the two valves inside the ERC causing minimum spillage.

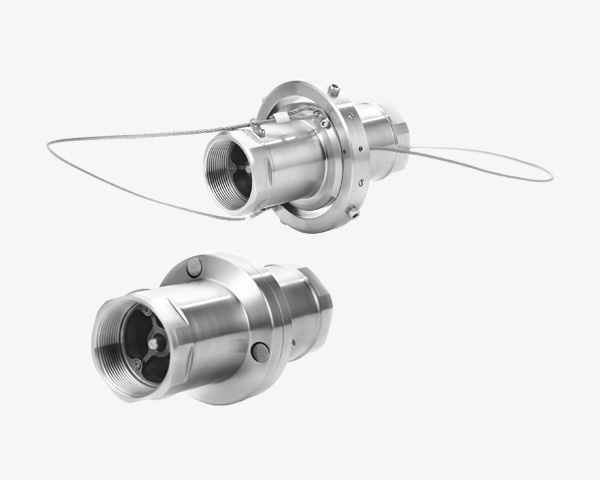

Cable Release Type (C-ERC)

Operation Philosophy

Non-axial forces are generated as the tanker moves in case of an emergency and these forces are transferred on the ERC spring plungers through a cable. With this the ERC gets separated with instant closing of the two valves inside the ERC causing minimum spillage.

Features

- No extra spares required to reassemble once activated

- Breaking force can be adjusted with same arrangement

Features of

S-ERC and

C-ERC

- Safe & Reliable

- Spill-free Separation

- High flow rate / Low pressure drop

- Simple design & easy to maintain onsite

- Coupling automatically senses an excessive load and closes the valves and disconnects

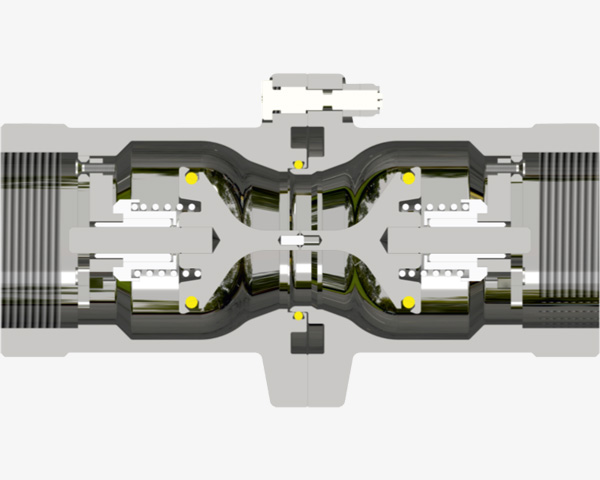

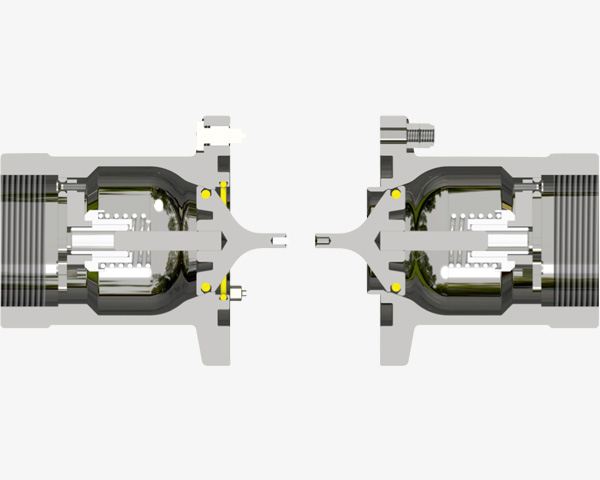

Working of ERC

Before and after emergency disconnect

In connection

The ERC consists of two halves and when connected allows maximum flow

After disconnection

When ERC activates and separates it allows the halves to close instantly thus ensuring leak proof spilling on both halves

Technical Specifications

Viton GFLT: -40°F to +212°F (-40°C to +100°C);

Nitrile/Buna: -22°F to 212°F (-30°C to +100°C);