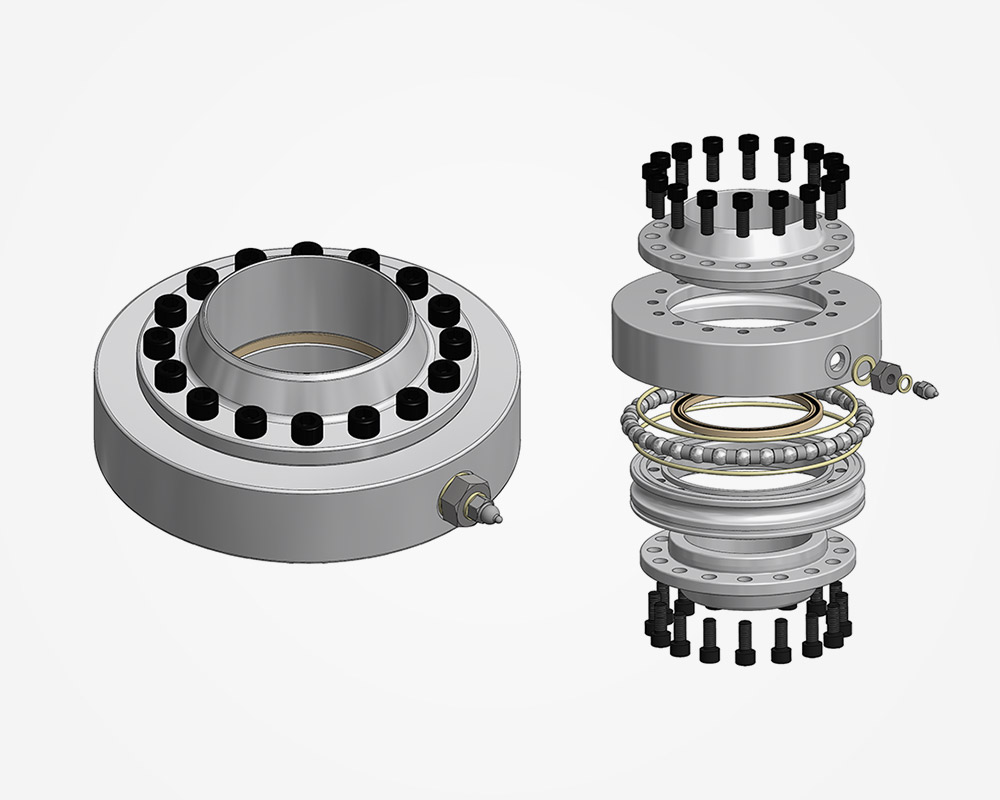

The heart of any loading arm or movable pipework system is the swivel joint. Woodfield Systems International WSS range of single ball race cassette style swivel joints have been specifically designed for heavy loads, smooth operation, ease of maintenance, and long life. And, with the added benefits of a super low profile and a replacement ball track cassette. For fuels, compressed gasses, chemical and industrial products, there is a WSS to meet the demands of each specific application…

WSS Features

- Single “big” ball race design for maximum load capacity. All ball track cassettes are hardened carbon steel

- Dual split flange design allows the product path material to be exactly matched with the product being handled. The ball track cassette is made from hardened carbon steel for maximum strength

- Split flange design also allows for maximum maintenance efficiency

- Sizes in 2” through 6”

- Standard flange (product path) materials of construction

- A105 Carbon steel

- 304L & 316L Stainless steel

- Forged Aluminium 6063-T6

- Specialty materials available:

- Duplex & Super Duplex stainless steel

- 904L Stainless steel

- Inconel

- Seal material to suit the application, typically Viton™, Nitrile, PTFE, Kalrez™

- MAWP up to 40 Bar

- Standard operating temperature range -40C to 240C (material and seal dependent)

- Standard 2 year limited warranty

WSS Options

- Nitrogen purged raceways

- Available in all standard “Styles”, 10 through 80

- Full selection of inlet and outlet connections:

- Threaded

- Flanged

- Union etc.

WSS Range

- Single ball race

- Dual split flange

- Hardened carbon steel ball track cassette

- Available flange materials: Carbon steel,

- 304L-316L-904L Stainless Steels,

- Aluminum,

- Duplex and Super Duplex, Inconel

- Viton, Nitrile, PTFE, Kalrez sealing options

- All “Style” available

- 2” through 6”