WSI’s range of Gas Loading Arms and Unloading Arms are specifically designed to handle liquefied gases like LNG and LPG. Whether for top or bottom loading or unloading of tank trucks or (Russian) railcars there is a WSI Gas Loading Arm to suit the application. All Gas Loading Arms and Unloading Arms are of modular design with flanged connections of all the major components, thus allowing easy arm configurations and superior maintenance capabilities. The inlet flange connection of our LPG Loading Arms and LNG Loading Arms will suit the application

FEATURES

- WSI's LPG loading arms and LNG Loading Arms are designed in accordance with applicable international standards

- Safe and easy handling of our LPG loading arms and LNG Loading Arms is assured

- All Gas Loading Arms are balanced by HD compression spring

- A variety of accessories like dry break couplers, quick couplers or emergency release systems are available, that the LNG or LPG Loading Arm will match the application

- LNG and LPG Loading and Unloading Arms are available in 2", 3" and 4"State of the art swivel joint technology and designs, proven over decades

- MOC: carbon steel, stainless steel or low temperature steelSeal materials Viton, PTFE or Kalrez, depending on the process parameter

- Design pressure: 25bar, higher on request

- Design temperature: -196°C to +80°C for LNG Loading Arms, -40°C to +80°C for LPG Loading Arms

- Gas Loading Arms are available as product and vapour recovery arm

- For bottom loading this can be carried out as Bottom Loading Station, e.g. two Gas Loading Arms (one for liquid and one for vapour) installed on a single standpost.

All WSI Gas Loading Arms are designed and manufactured within our certified ISO quality management systems and in line with ASME 831.3 Process Piping code. All loading arms and swivel joint assemblies are 100% hydro tested. Dye penetrant testing and Radiography carried out to required specifications. Full manufacturing documentation and MTR's can be provided with each Gas Loading Arm. Standard paint finish for carbon steel is shot blasting to SA 2 1/2 and Poly Urethane RAL 7035 paint finish. Specific painting specifications also provided. If required, TPI will be provided

BOTTOM LOADING ARMS

WSI range of bottom loading arms are specifically engineered to handle the unique nature of liquid compressed gasses and vapors transported in tank trucks or railcars, or trans-loaded between the two. Up to #300 rated with minimal flanged connections in carbon steel and stainless steel to handle refined products such as LPG, Propane, Butane, Isobutene, Anhydrous Ammonia, LNG as well as course unrefined NGL's.

Typical size is 2" but larger 3" and 4" are available for specialized applications. For longer reach applications a 3" arm is usually better suited for structural strength with a 2" connection point to the tank truck or railcar.

Connection devises will vary with different applications. Each WSI compressed gas bottom loading arm is designed to work with either, dry-gas couplers and adapters, hammer unions or lap flange connection points. Outboard swivel joints are incorporated in to each bottom loading arm with multiple flow control and connection options. Isolation valves, breakaway devices and remote shut down devices can all be incorporated in to each configuration of bottom loading arm arm.

All bottom loading arms are offered in standard length configurations or custom sized to suit the exact application

All WSI bottom loading arms are designed and manufactured within our certified ISO quality management systems and in line with ASME 831.3 Process Piping code. All bottom loading arms and swivel joint assemblies are100% hydro tested. Dye penetrant testing and Radiography are also carried out to required specifications. Full manufacturing documentation and MTR's can be provided with each loading arm. Standard paint finish for carbon steel is shot blasting to SA 2 1/2 and Poly Urethane RAL 7035 paint finish. Specific painting specifications are also provided. If required, TPI will be provided.

- W720 LONG REACH

(UNSUPPORTED) - W820 LONG REACH

(SUPPORTED) - W820-L LONG REACH

(SUPPORTED) - W920 ‘A’ FRAME

- W920-H ‘A’ FRAME

W720 LONG REACH

(UNSUPPORTED)

DETAILS

The W720 Long Reach (unsupported) bottom loading/unloading arm is ideal for transferring compressed gas liquids and vapors to or from tank trucks or rail cars. The W720’s long reach enables greater flexibility with miss-spotting or obstructions from other rail car and tank truck equipment

The W720’s long reach and signi cant miss-spot capabilities are due to a swivel boom that extends “unsupported” from the riser on the stand post. This provides an extra plane or rotation and allows the loading arm to track a distance along the bottom side of a rail car, or bottom side or rear of a tank truck

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand

Up Feed or Down Feed

Side Feed

FEATURES

- Typical range of vertical movement is +50° park position to -10° load position.

- Typical boom length of 1500mm. Primary length is 1,500 mm to 2,000mm with an Outboard 2-plane Style-70 swivel joint and operating handle. All dimensions can be changed to suit each application.

- Made from all carbon steel or stainless steel.

- An isolation valve can be incorporated and outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

W820 LONG REACH

(SUPPORTED)

DETAILS

The W820 Long Reach (supported) bottom loading/unloading arm is ideal for transferring compressed gas liquids and vapors to or from tank trucks or rail cars. The W820’s long reach enables greater flexibility with miss-spotting or obstructions from other rail car and tank truck equipment and can carry more additional equipment on the loading arm. Often used for carrying a vapor hose “piggy back” to the loading arm.

The W820’s long reach and signi cant miss-spot capabilities are due to a swivel boom that extends “supported” from the riser on the stand post. This provides an extra plane or rotation and allows the loading arm to track a distance along the bottom side of a rail car, or bottom side or rear of a tank truck.

AVAILABLE SIZES

2”, 3” x 2”, 3 or 4”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +50° park position to -10° load position.

- Typical boom length of 1500mm. Primary length is 1,500 mm to 2,000mm with an Outboard 2-plane Style-70 swivel joint and operating handle. All dimensions can be changed to suit each application.

- Made from all carbon steel or stainless steel.

- An isolation valve can be incorporated and outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

W820-L LONG REACH

(SUPPORTED)

DETAILS

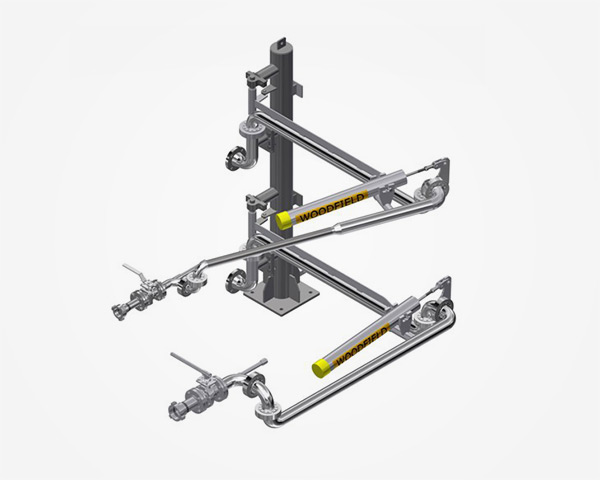

The W820-L Loading station is purpose designed for bottom transfer of compressed gas liquids and vapor transfer to/from tank trucks or rail cars. The W820-L is a complete loading/unloading station incorporating a liquid carrying arm and a vapor transfer arm mounted together on a common stand post.

Both loading/unloading arms are long reach supported boom style for maximum reach and miss-spot orientation plus both have the ability to carry additional outboard equipment such as isolation valves, breakaway couplings and dry-gas couplers

The W820’s long reach and signi cant miss-spot capabilities are due to a swivel boom that extends “supported” from the riser on the stand post. This provides an extra plane or rotation and allows the loading arm to track a distance along the bottom side of a rail car, or bottom side or rear of a tank truck.

AVAILABLE SIZES

2”, 3” x 2”, 3 or 4”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +50° park position to -10° load position.

- Typical boom length of 1500mm. Primary length is 1,500 mm to 2,000mm with an Outboard 2-plane Style-70 swivel joint and operating handle. All dimensions can be changed to suit each application.

- Made from all carbon steel or stainless steel.

- An isolation valve can be incorporated and outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

W920 ‘A’ FRAME

DETAILS

W920 ‘A’ Frame bottom loading/unloading arms for compressed liquid gasses and vapor transfer are ideal for loading/unloading tank trucks and rail cars. ‘A’ Frame loading arms have an advantage when the lanes are narrow or where servicing both sides of the lane is required. For tank trucks, ‘A’ Frame bottom loading/unloading arms can also service the rear of the vehicle.

W920 has a solid drop pipe, 2-plane Style-50 Outboard swivel joint with handle and an option of a ball valve to allow for orientation as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, or 3

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +60°/+30°

- Typical primary length of 1,500mm, Drop tube of 1,800mm with Style-30 Outboard swivel joint and handle at the outboard. All dimensions can be changed to suit each application.

- Made from all carbon steel or stainless steel.

W920-H ‘A’ FRAME

DETAILS

W920-H ‘A’ Frame bottom loading/unloading arms for compressed liquid gasses and vapor transfer are ideal for loading/unloading tank trucks and rail cars. ‘A’ Frame loading arms have an advantage when the lanes are narrow or where servicing both sides of the lane is required. For tank trucks, ‘A’ Frame bottom loading/unloading arms can also service the rear of the vehicle

W920-H has a 2” SS drop hose, 90° Style-30 Outboard swivel joint and handle with an option of a 2” ball valves to allow for orientation as well as controlling the supply to/from the loading arm

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, or 3

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +60°/+30° Typical primary length of 1,500mm, Drop hose of 1,800mm with Style-30 Outboard swivel joint and handle at the outboard. All dimensions can be changed to suit each application.

- Made from all carbon steel or stainless steel.

BOTTOM UNLOADING ARMS

WSI range of Bottom unloading arms are specifically engineered to handle the unique nature of liquid compressed gasses and vapors transported in tank trucks or railcars, or trans-loaded between the two. Up to #300 rated with minimal flanged connections in carbon steel and stainless steel to handle refined products such as LPG, Propane, Butane, Isobutene, Anhydrous Ammonia, LNG as well as course unrefined NGL's.

Typical size is 2" but larger 3" and 4" are available for specialized applications. For longer reach applications a 3" arm is usually better suited for structural strength with a 2" connection point to the tank truck or railcar.

Connection devises will vary with different applications. Each WSI compressed gas bottom unloading arm is designed to work with either, dry-gas couplers and adapters, hammer unions or lap flange connection points. Outboard swivel joints are incorporated in to each bottom unloading arm with multiple flow control and connection options. Isolation valves, breakaway devices and remote shut down devices can all be incorporated in to each configuration of bottom unloading arm.

All unloading arms are offered in standard length configurations or custom sized to suit the exact application.

All WSI bottom unloading arms are designed and manufactured within our certified ISO quality management systems and in line with ASME 831.3 Process Piping code. All bottom loading arms and swivel joint assemblies are100% hydro tested. Dye penetrant testing and Radiography are also carried out to required specifications. Full manufacturing documentation and MTR's can be provided with each bottom unloading arm. Standard paint finish for carbon steel is shot blasting to SA 2 1/2 and Poly Urethane RAL 7035 paint finish. Specific painting specifications are also provided. If required, TPI will be provided.

- W720 LONG REACH

(UNSUPPORTED) - W820 LONG REACH

(SUPPORTED) - W820-L LONG REACH

(SUPPORTED)

W720 LONG REACH

(UNSUPPORTED)

DETAILS

The W720 Long Reach (unsupported) bottom loading/unloading arm is ideal for transferring compressed gas liquids and vapors to or from tank trucks or rail cars. The W720’s long reach enables greater flexibility with miss-spotting or obstructions from other rail car and tank truck equipment

The W720’s long reach and signi cant miss-spot capabilities are due to a swivel boom that extends “unsupported” from the riser on the stand post. This provides an extra plane or rotation and allows the loading arm to track a distance along the bottom side of a rail car, or bottom side or rear of a tank truck.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand

Up Feed or Down Feed

Side Feed

FEATURES

- Typical range of vertical movement is +50° park position to -10° load position.

- Typical boom length of 1500mm. Primary length is 1,500 mm to 2,000mm with an Outboard 2-plane Style-70 swivel joint and operating handle. All dimensions can be changed to suit each application.

- Made from all carbon steel or stainless steel.

- An isolation valve can be incorporated and outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

W820 LONG REACH

(SUPPORTED)

DETAILS

The W820 Long Reach (supported) bottom loading/unloading arm is ideal for transferring compressed gas liquids and vapors to or from tank trucks or rail cars. The W820’s long reach enables greater flexibility with miss-spotting or obstructions from other rail car and tank truck equipment and can carry more additional equipment on the loading arm. Often used for carrying a vapor hose “piggy back” to the loading arm.

The W820’s long reach and signi cant miss-spot capabilities are due to a swivel boom that extends “supported” from the riser on the stand post. This provides an extra plane or rotation and allows the loading arm to track a distance along the bottom side of a rail car, or bottom side or rear of a tank truck.

AVAILABLE SIZES

2”, 3” x 2”, 3 or 4”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +50° park position to -10° load position.

- Typical boom length of 1500mm. Primary length is 1,500 mm to 2,000mm with an Outboard 2-plane Style-70 swivel joint and operating handle. All dimensions can be changed to suit each application.

- Made from all carbon steel or stainless steel.

- An isolation valve can be incorporated and outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

W820-L LONG REACH

(SUPPORTED)

DETAILS

The W820-L Loading station is purpose designed for bottom transfer of compressed gas liquids and vapor transfer to/from tank trucks or rail cars. The W820-L is a complete loading/unloading station incorporating a liquid carrying arm and a vapor transfer arm mounted together on a common stand post.

Both loading/unloading arms are long reach supported boom style for maximum reach and miss-spot orientation plus both have the ability to carry additional outboard equipment such as isolation valves, breakaway couplings and dry-gas couplers.

The W820’s long reach and signi cant miss-spot capabilities are due to a swivel boom that extends “supported” from the riser on the stand post. This provides an extra plane or rotation and allows the loading arm to track a distance along the bottom side of a rail car, or bottom side or rear of a tank truck.

AVAILABLE SIZES

2”, 3” x 2”, 3 or 4”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +50° park position to -10° load position.

- Typical boom length of 1500mm. Primary length is 1,500 mm to 2,000mm with an Outboard 2-plane Style-70 swivel joint and operating handle. All dimensions can be changed to suit each application.

- Made from all carbon steel or stainless steel.

- An isolation valve can be incorporated and outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

TOP LOADING ARMS

WSI range of Top loading arms are specifically engineered to handle the unique nature of liquid compressed gasses and vapors transported in tank trucks or railcars, or trans-loaded between the two. Up to #300 rated with minimal flanged connections in carbon steel and stainless steel to handle refined products such as LPG, Propane, Butane, Isobutene, Anhydrous Ammonia, LNG as well as course unrefined NGL's.

Typical size is 2" but larger 3" and 4" are available for specialist applications. For longer reach applications a 3" arm is usually better suited for structural strength with a 2" connection point to the tank truck or railcar.

Connection devises will vary with different applications. Each WSI compressed gas loading/unloading arm is designed to work with either, dry-gas couplers and adapters, hammer unions or lap flange connection points. Outboard swivel joints are incorporated in to each loading arm with multiple flow control and connection options. Isolation valves, breakaway devices and remote shut down devices can all be incorporated in to each configuration of top or bottom, loading or unloading arm.

All loading/unloading arms are offered in standard length configurations or custom sized to suit the exact application.

All WSI loading arms are designed and manufactured within our certified ISO quality management systems and in line with ASME B31.3 Process Piping code. All loading arms and swivel joint assemblies are100% hydro tested. Dye penetrant testing and Radiography carried out to required specifications. Full manufacturing documentation and MTRs can be provided with each loading arm. Standard paint finish for carbon steel is shot blasting to SA 21 and Poly Urethane RAL 7035 paint finish. Specific painting specifications also provided. If required, TPI will be provided.

- W120-H FIXED REACH

- W120 FIXED REACH

- W320-H LONG REACH

(UNSUPPORTED) - W320 LONG REACH

(UNSUPPORTED) - W420-H LONG REACH

(SUPPORTED) - W420 LONG REACH

(SUPPORTED) - Dual W420-DH LONG REACH

(SUPPORTED)

W120-H FIXED REACH

DETAILS

The W120-H Fixed Reach is ideal for transferring compressed gas liquids and vapors to or from the top of rail cars provided the cars can be accurately spotted (positioned) each time. Fixed reach loading arms have limited capability to accommodate miss-spotted railcars.

W120-H has a 2” SS drop hose, and 90° Style-30 swivel joint with option of a 2” ball valve to allow for orientation on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway coupling, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand

Up Feed or Down Feed

Side Feed

FEATURES

- Typical range of vertical movement is +70° park position to -20° load position

- Made from all carbon steel or stainless steel.

- Typical range of primary length is 2,000mm to 2,500mm with a 1,200mm drop pipe and Style-50 assembly. All dimensions can be changed to suit each application.

W120 FIXED REACH

DETAILS

The W120 Fixed Reach is ideal for transferring compressed gas liquids and vapors to or from the top of rail cars provided the cars can be accurately spotted (positioned) each time. Fixed reach loading arms have limited capability to accommodate miss-spotted railcars.

W120 has a solid drop pipe and a 2-plane Style-50 Outboard swivel joint assembly with an option of a 2” ball valve to allow for orientation on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +70° park position to -20° load position

- Made from all carbon steel or stainless steel.

- Typical range of primary length is 2,000mm to 2,500mm with a 1,200mm drop pipe and Style-50 assembly. All dimensions can be changed to suit each application.

W320-H LONG REACH

(UNSUPPORTED)

DETAILS

W320-H long reach top loading arms are designed speci cally for loading/unloading compressed gas liquids and vapors from and to railcars where miss-spotting is likely i.e. when connecting with a line of coupled varying length railcar tanks. The W320-H’s longer reach and miss-spot capabilities are due to a “swivel boom” that extends “unsupported” from the riser on to which a xed reach loading arm is attached. This provides an extra plane or rotation and allows the loading arm to “track” a considerable distance along the centerline of a railcar.

W320-H has a 2” SS drop hose, 90° Style-30 Outboard swivel joint assembly with an option of a 2” ball valve to allow for orientation on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +70° park position to -20° load position

- Made from all carbon steel or stainless steel.

- Typical boom length is 1,500mm. Primary length is 2,000mm to 2,300mm with a 1,500mm drop hose and Style-30 Outboard swivel joint assembly. All dimensions can be changed to suit each application.

W320 LONG REACH

(UNSUPPORTED)

DETAILS

W320 long reach top loading arms are designed speci cally for loading/unloading compressed gas liquids and vapors from and to railcars where miss-spotting is likely i.e. when connecting with a line of coupled varying length railcar tanks. The W320’s longer reach and miss-spot capabilities are due to a “swivel boom” that extends “unsupported” from the riser on to which a xed reach loading arm is attached. This provides an extra plane or rotation and allows the loading arm to “track” a considerable distance along the centerline of a railcar.

W320 has a solid drop pipe, 2-plane Style-50 Outboard swivel joint with an option of a 2” ball valve to allow for orientation on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +70° park position to -20° load position.

- Made from all carbon steel or stainless steel.

- Typical boom length is 1,500mm. Primary length is 2,000mm to 2,300mm with a 1,500mm drop pipe and Style-50 swivel assembly. All dimensions can be changed to suit each application.

W420-H LONG REACH

(SUPPORTED)

DETAILS

W420 long reach top loading arms are designed speci cally for loading/unloading compressed gas liquids and vapors from and to railcars where a signi cant miss-spotting capacity is required and additional equipment is to be carried by the arm. i.e. when connecting with a line of coupled varying length railcar tanks and breakaway devices are to be incorporated. The W420’s longer reach and signi cant miss-spot capabilities are due to a “swivel boom” that extends “supported” from the riser on to which a xed reach loading arm is attached. This provides an extra plane or rotation and allows the loading arm to “track” a considerable distance along the centerline of the railcar as well as carry additional weight.

W420 has a solid drop pipe, 2-plane Style-50 Outboard swivel joint with an option of a 2” ball valve to allow for orientation on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +70° park position to -20 load position.

- Made from all carbon steel or stainless steel.

- Typical boom length is 1,500mm. Primary length is 2,000mm to 2,300mm with a 1,500mm drop pipe and Style-50 Outboard swivel assembly. All dimensions can be changed to suit each application.

W420 LONG REACH

(SUPPORTED)

DETAILS

W420 long reach top loading arms are designed speci cally for loading/unloading compressed gas liquids and vapors from and to railcars where a signi cant miss-spotting capacity is required and additional equipment is to be carried by the arm. i.e. when connecting with a line of coupled varying length railcar tanks and breakaway devices are to be incorporated. The W420’s longer reach and signi cant miss-spot capabilities are due to a “swivel boom” that extends “supported” from the riser on to which a xed reach loading arm is attached. This provides an extra plane or rotation and allows the loading arm to “track” a considerable distance along the centerline of the railcar as well as carry additional weight.

W420 has a solid drop pipe, 2-plane Style-50 Outboard swivel joint with an option of a 2” ball valve to allow for orientation on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +70° park position to -20 load position.

- Made from all carbon steel or stainless steel.

- Typical boom length is 1,500mm. Primary length is 2,000mm to 2,300mm with a 1,500mm drop pipe and Style-50 Outboard swivel assembly. All dimensions can be changed to suit each application.

Dual W420-DH LONG REACH

(SUPPORTED)

DETAILS

W420-DH long reach, dual connection top loading arms are designed speci cally for loading/unloading compressed gas liquids from and to railcars where signi cant missspotting capacity is required and both liquid connections on the rail car are to be used. The W420-DH’s longer reach and signi cant miss-spot capabilities are due to a “swivel boom” that extends “supported” from the riser on to which a xed reach loading arm is attached. This provides an extra plane or rotation and allows the loading arm to “track” a considerable distance along the centerline of the railcar. Dual drop hoses are attached at the apex swivel joint via a “cross bar” which spreads the dual drop hose assemblies across the width of the manhole so both liquid connections can be orientated and simply connected

W420-H has 2 x 2” SS drop hoses, 2 x 90° Style-30 Outboard swivel joints with an option of a 2 x 2” ball valves to allow for orientation to both liquid connections on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +70° park position to -20° load position

- Made from all carbon steel or stainless steel.

- A separate 2” vapor hose can be “piggy backed” to the loading arm to guide and connect/disconnect both liquid connections as well as the vapor connection at the same time without orientating a separate piece of hose

- Typical boom length is 1,800mm. Primary length is 2,000mm to 2,500mm with a 1,500mm drop hose and Style-30 swivel joint.

TOP UNLOADING ARMS

WSI range of top unloading arms are specifically engineered to handle the unique nature of liquid compressed gasses and vapours transported in tank trucks or railcars, or trans-loaded between the two. Up to #300 rated with minimal flanged connections in carbon steel and stainless steel to handle refined products such as LPG, Propane, Butane, Isobutene, Anhydrous Ammonia, LNG as well as course unrefined NGL's.

Typical size is 2" but larger 3" and 4" are available for specialist applications. For longer reach applications a 3" arm is usually better suited for structural strength with a 2" connection point to the tank truck or railcar. .

Connection devises will vary with different applications. Each WSI compressed gas loading/unloading arm is designed to work with either, dry-gas couplers and adapters, hammer unions or lap flange connection points. Outboard swivel joints are incorporated in to each loading arm with multiple flow control and connection options. Isolation valves, breakaway devices and remote shut down devices can all be incorporated in to each configuration of top or bottom, loading or unloading arm.

All loading/unloading arms are offered in standard length configurations or custom sized to suit the exact application.

All WSI loading arms are designed and manufactured within our certified ISO quality management systems and in line with ASME B31.3 Process Piping code. All loading arms and swivel joint assemblies are100% hydro tested. Dye penetrant testing and Radiography carried out to required specifications. Full manufacturing documentation and MTRs can be provided with each loading arm. Standard paint finish for carbon steel is shot blasting to SA 2'h and Poly Urethane RAL 7035 paint finish. Specific painting specifications also provided. If required, TPI will be provided

- W120 FIXED REACH

- W320-H LONG REACH

(UNSUPPORTED) - W320 LONG REACH

(UNSUPPORTED) - W420-H LONG REACH

(SUPPORTED) - W420 LONG REACH

(SUPPORTED) - Dual W420-DH LONG REACH

(SUPPORTED)

W120 FIXED REACH

DETAILS

The W120 Fixed Reach is ideal for transferring compressed gas liquids and vapors to or from the top of rail cars provided the cars can be accurately spotted (positioned) each time. Fixed reach loading arms have limited capability to accommodate miss-spotted railcars.

W120 has a solid drop pipe and a 2-plane Style-50 Outboard swivel joint assembly with an option of a 2” ball valve to allow for orientation on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +70° park position to -20° load position

- Made from all carbon steel or stainless steel.

- Typical range of primary length is 2,000mm to 2,500mm with a 1,200mm drop pipe and Style-50 assembly. All dimensions can be changed to suit each application.

W320-H LONG REACH

(UNSUPPORTED)

DETAILS

W320-H long reach top loading arms are designed speci cally for loading/unloading compressed gas liquids and vapors from and to railcars where miss-spotting is likely i.e. when connecting with a line of coupled varying length railcar tanks. The W320-H’s longer reach and miss-spot capabilities are due to a “swivel boom” that extends “unsupported” from the riser on to which a xed reach loading arm is attached. This provides an extra plane or rotation and allows the loading arm to “track” a considerable distance along the centerline of a railcar.

W320-H has a 2” SS drop hose, 90° Style-30 Outboard swivel joint assembly with an option of a 2” ball valve to allow for orientation on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +70° park position to -20° load position

- Made from all carbon steel or stainless steel.

- Typical boom length is 1,500mm. Primary length is 2,000mm to 2,300mm with a 1,500mm drop hose and Style-30 Outboard swivel joint assembly. All dimensions can be changed to suit each application.

W320 LONG REACH

(UNSUPPORTED)

DETAILS

W320 long reach top loading arms are designed speci cally for loading/unloading compressed gas liquids and vapors from and to railcars where miss-spotting is likely i.e. when connecting with a line of coupled varying length railcar tanks. The W320’s longer reach and miss-spot capabilities are due to a “swivel boom” that extends “unsupported” from the riser on to which a xed reach loading arm is attached. This provides an extra plane or rotation and allows the loading arm to “track” a considerable distance along the centerline of a railcar.

W320 has a solid drop pipe, 2-plane Style-50 Outboard swivel joint with an option of a 2” ball valve to allow for orientation on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +70° park position to -20° load position.

- Made from all carbon steel or stainless steel.

- Typical boom length is 1,500mm. Primary length is 2,000mm to 2,300mm with a 1,500mm drop pipe and Style-50 swivel assembly. All dimensions can be changed to suit each application.

W420-H LONG REACH

(SUPPORTED)

DETAILS

W420 long reach top loading arms are designed speci cally for loading/unloading compressed gas liquids and vapors from and to railcars where a signi cant miss-spotting capacity is required and additional equipment is to be carried by the arm. i.e. when connecting with a line of coupled varying length railcar tanks and breakaway devices are to be incorporated. The W420’s longer reach and signi cant miss-spot capabilities are due to a “swivel boom” that extends “supported” from the riser on to which a xed reach loading arm is attached. This provides an extra plane or rotation and allows the loading arm to “track” a considerable distance along the centerline of the railcar as well as carry additional weight.

W420 has a solid drop pipe, 2-plane Style-50 Outboard swivel joint with an option of a 2” ball valve to allow for orientation on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +70° park position to -20 load position.

- Made from all carbon steel or stainless steel.

- Typical boom length is 1,500mm. Primary length is 2,000mm to 2,300mm with a 1,500mm drop pipe and Style-50 Outboard swivel assembly. All dimensions can be changed to suit each application.

W420 LONG REACH

(SUPPORTED)

DETAILS

W420 long reach top loading arms are designed speci cally for loading/unloading compressed gas liquids and vapors from and to railcars where a signi cant miss-spotting capacity is required and additional equipment is to be carried by the arm. i.e. when connecting with a line of coupled varying length railcar tanks and breakaway devices are to be incorporated. The W420’s longer reach and signi cant miss-spot capabilities are due to a “swivel boom” that extends “supported” from the riser on to which a xed reach loading arm is attached. This provides an extra plane or rotation and allows the loading arm to “track” a considerable distance along the centerline of the railcar as well as carry additional weight.

W420 has a solid drop pipe, 2-plane Style-50 Outboard swivel joint with an option of a 2” ball valve to allow for orientation on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +70° park position to -20 load position.

- Made from all carbon steel or stainless steel.

- Typical boom length is 1,500mm. Primary length is 2,000mm to 2,300mm with a 1,500mm drop pipe and Style-50 Outboard swivel assembly. All dimensions can be changed to suit each application.

Dual W420-DH LONG REACH

(SUPPORTED)

DETAILS

W420-DH long reach, dual connection top loading arms are designed speci cally for loading/unloading compressed gas liquids from and to railcars where signi cant missspotting capacity is required and both liquid connections on the rail car are to be used. The W420-DH’s longer reach and signi cant miss-spot capabilities are due to a “swivel boom” that extends “supported” from the riser on to which a xed reach loading arm is attached. This provides an extra plane or rotation and allows the loading arm to “track” a considerable distance along the centerline of the railcar. Dual drop hoses are attached at the apex swivel joint via a “cross bar” which spreads the dual drop hose assemblies across the width of the manhole so both liquid connections can be orientated and simply connected

W420-H has 2 x 2” SS drop hoses, 2 x 90° Style-30 Outboard swivel joints with an option of a 2 x 2” ball valves to allow for orientation to both liquid connections on top of the rail car as well as controlling the supply to/from the loading arm.

Outboard connections can be dry-gas coupler, hammer union or lap flange to suit the application. Breakaway couplings, remote shut down devices and purge systems can be incorporated as required.

AVAILABLE SIZES

2”, 3” x 2”, and 3”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand,

Up feed or Down feed and

Side feed

FEATURES

- Typical range of vertical movement is +70° park position to -20° load position

- Made from all carbon steel or stainless steel.

- A separate 2” vapor hose can be “piggy backed” to the loading arm to guide and connect/disconnect both liquid connections as well as the vapor connection at the same time without orientating a separate piece of hose

- Typical boom length is 1,800mm. Primary length is 2,000mm to 2,500mm with a 1,500mm drop hose and Style-30 swivel joint.