The chemical and industrial products industry faces various critical loading and unloading challenges. Many products such as molten sulphur, bitumen and some crude oils require to be handled at specific high temperatures during the transfer process. In extreme cold climates heated arms are used to prevent product solidifying. This is why all WSI top and bottom loading & unloading arms are available as a "heated" model available with;

External steam or oil jacketing, or Electric heat tracing

All WSI arms come with custom insulation jackets to reduce heat/energy loss. Insulation jackets are removable for inspection/maintenance. Aluminium clad insulation can also be provided as required.

WSI's range of Top and Bottom Heated Loading arms or unloading arms are specifically engineered to handle the exact nature of each liquid or vapor being handled in and out of tank trucks, rail cars and ISO container tanks. For all temperature dependent liquids and vapors WSI has a specific solution to handle each application safely and successfully.

FEATURES

- Sizes in 3” x 2”, 4” x 3”, 6” x 4” and 8” x 6”

- Materials of construction: Carbon steels, Stainless steel.

- Special Material: Super Duplex, 904L SS etc.

- Dual race Split Flange WL2 or Single race WSS swivel joints

- Seals in Viton™, Hydrogenated Buna, PTFE etc. to suit the specific application

- Swivel joint leak detection systems

- Compression spring, counterweight, pneumatic or hydraulic balance control systems

- Top and bottom loading station configurations (stand post)

- Vapor recovery

- High-level detection systems

- Purging systemsControl valvesPosition sensorsCouplers and adapters

All WSI heated loading and unloading arms are designed and manufactured within our certified ISO quality management systems and in line with ASME B31.3 Process Piping code.

All heated loading arms, unloading arms and swivel joint assemblies are100% hydro tested. Dye penetrant testing and Radiography are carried out to required specifications. Full manufacturing documentation and MTR’s are provided with each heated loading and unloading arm. Standard paint finish for carbon steel is shot blasted to SA 2 ½ and Poly Urethane RAL 7035 paint finish. Specific painting specifications are also provided. If required, TPI will also be provided.

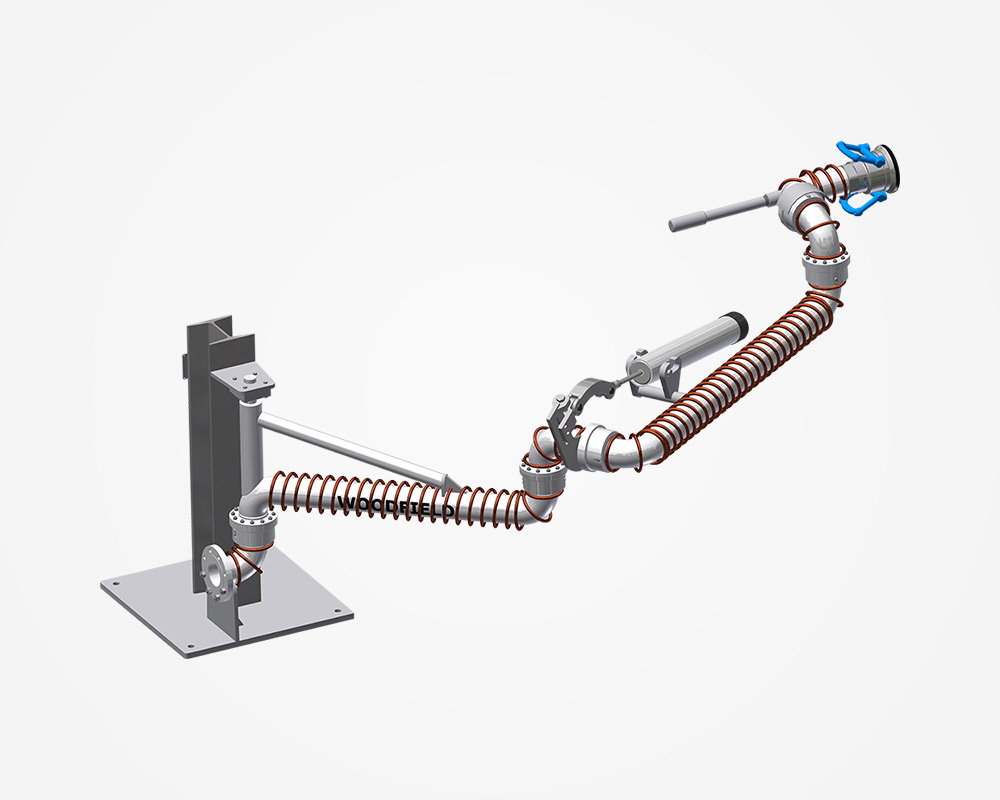

Electric Heat traced Bottom

Loading & UNLOADING ARMS

Bottom Loading or Unloading of highly viscous material is most challenging. Products like Bitumen, Asphalt, Molten Sulphur, etc. are extremely tricky to handle. WSI's electric traced bottom loading & unloading arms are ideal for such products that require minimal/no heat loss during transfer to tank trucks, rail cars, ISO container tanks and where signi cant miss-spotting is likely and additional equipment is carried by the bottom loading & unloading arm.

- W840 PT LONG REACH

W840 PT LONG REACH

DETAILS

W840-PT Electrically Heat Traced long reach bottom loading arms are ideal for industrial products that require minimal/no heat loss during transfer to tank trucks, rail cars and ISO container tanks, and where additional equipment is carried by the loading arm.

The W840-PT’s longer reach and significant miss-spot capabilities are due to a “supported swivel boom” that extends from the riser on the stand post and to which a xed reach loading arm is attached. The supported boom allows for superior weight carrying capacity necessary for carrying heat tracing and insulation. A two plane Outboard Style-70 swivel joint with a handle allows lightweight and simple coupling to the vehicle. Multiple tank connection formats available. EX zoning speci cations where required

AVAILABLE SIZES

3” x 2”, 4” x 3”, 6” x 4”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand

Up Feed or Down Feed

Side Feed all mounted on a stand post

FEATURES

- Materials of construction: Carbon steels, 304L and 316L stainless steel Exotic alloys for specialty applications where applicable: Duplex Stainless Steel, Super Duplex Stainless Steel, 904L Stainless Steel, etc.

- Seals in Viton™, Nitrile, EPDM, PTFE, Kalrez™ etc. to suit the application

- Compression spring, counterweight, pneumatic or hydraulic balance control systems

- Typical boom length of 1700mm, with primary and outboard swivel at 1600mm. All dimensions can be changed to suit each application.

- Typical range of vertical movement is +50°/-10°

Electric Heat traced

Top LOADING ARMS

Top loading of highly viscous material is most challenging. Products like Bitumen, Asphalt, Molten Sulphur, etc. are extremely tricky to handle. WSI's electric traced top loading arms are ideal for such products that require minimal/no heat loss during transfer to tank trucks, rail cars, ISO container tanks and where signi cant miss-spotting is likely and additional equipment is carried by the loading arm.

- W440 PT LONG REACH

W440 PT LONG REACH

DETAILS

W440-PT Electrical Heat Traced long reach top loading arms are ideal for industrial products that require minimal/no heat loss during transfer to tank trucks and rail cars, and where signi cant miss-spotting is likely and additional equipment is carried by the loading arm.

The W440-PT’s longer reach and significant miss-spot capabilities are due to a “supported swivel boom” that extends from the riser on the stand post and to which a xed reach loading arm is attached. The supported boom allows for even longer range and/or superior weight carrying capacity necessary for carrying heat tracing and insulation. The supported boom provides an extra plane of rotation and allows the loading arm to “track” a considerable distance along the centerline of the tank truck, rail car or ISO tank container. Multiple drop pipe options available. Electrical heat tracing to EX zoning speci cations where required

AVAILABLE SIZES

3” x 2”, 4” x 3”, 6” x 4” and 8” x 6”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand

Up Feed or Down Feed

Side Feed all mounted on a stand post

FEATURES

- Materials of construction: Carbon steels, 304L and 316L stainless steel Exotic alloys for specialty applications where applicable: Duplex Stainless Steel, Super Duplex Stainless Steel, 904L Stainless Steel, etc.

- Seals in Viton™, Nitrile, EPDM, PTFE, Kalrez™ etc. to suit the application

- Compression spring, counterweight, pneumatic or hydraulic balance control systems

- Typical range of vertical movement is +70° park position to -20° load position. Typical “supported boom” length is 2,000mm, and typical range of primary length is 2,000mm to 2,800mm with a 1,500mm drop tube. All dimensions can be changed to suit each application.

- Typical range of vertical movement is +50°/-10°

- Alternative drop tube arrangements are available to suit the speci c application

Jacketed Bottom Loading &

UNLOADING ARMS

Bottom loading & unloading of highly viscous material is most challenging. Products like Bitumen, Asphalt, Molten Sulphur, etc. are extremely tricky to handle. WSI's Jacketed bottom loading & unloading arms are ideal for such products that require minimal/no heat loss during transfer to tank trucks, rail cars, ISO container tanks and where signi cant miss-spotting is likely and additional equipment is carried by the loading arm.

- W840 PJ LONG REACH

W840 PJ LONG REACH

DETAILS

W840 PJ Steam Jacketed long reach bottom loading arms are ideal for industrial products that require minimal/no heat loss during transfer to tank trucks, rail cars and ISO container tanks, and where additional equipment is carried by the loading arm.

The W840-PJ’s longer reach and significant miss spot capabilities are due to a “supported swivel boom” that extends from the riser on the stand post and to which a xed reach loading arm is attached. The supported boom allows for superior weight carrying capacity necessary for carrying steam jacketing and insulation. A two plane Outboard Style-70 swivel joint with a handle allows lightweight and simple coupling to the vehicle. Multiple tank connection formats available.

AVAILABLE SIZES

3” x 2”, 4” x 3”, 6” x 4”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand

Up Feed or Down Feed

Side Feed all mounted on a stand post

FEATURES

- Materials of construction: Carbon steels, aluminum and stainless steel. Exotic alloys, Duplex Stainless Steel, Super Duplex Stainless Steel, 904L Stainless Steel.

- Seals in Viton™, Nitrile, EPDM, PTFE, Kalrez™ etc. to suit the application

- Compression spring, counterweight, pneumatic or hydraulic balance control systems

- Typical boom length of 1700mm, with primary and outboard swivel at 1600mm. All dimensions can be changed to suit each application.

- Typical range of vertical movement is +50°/-10°

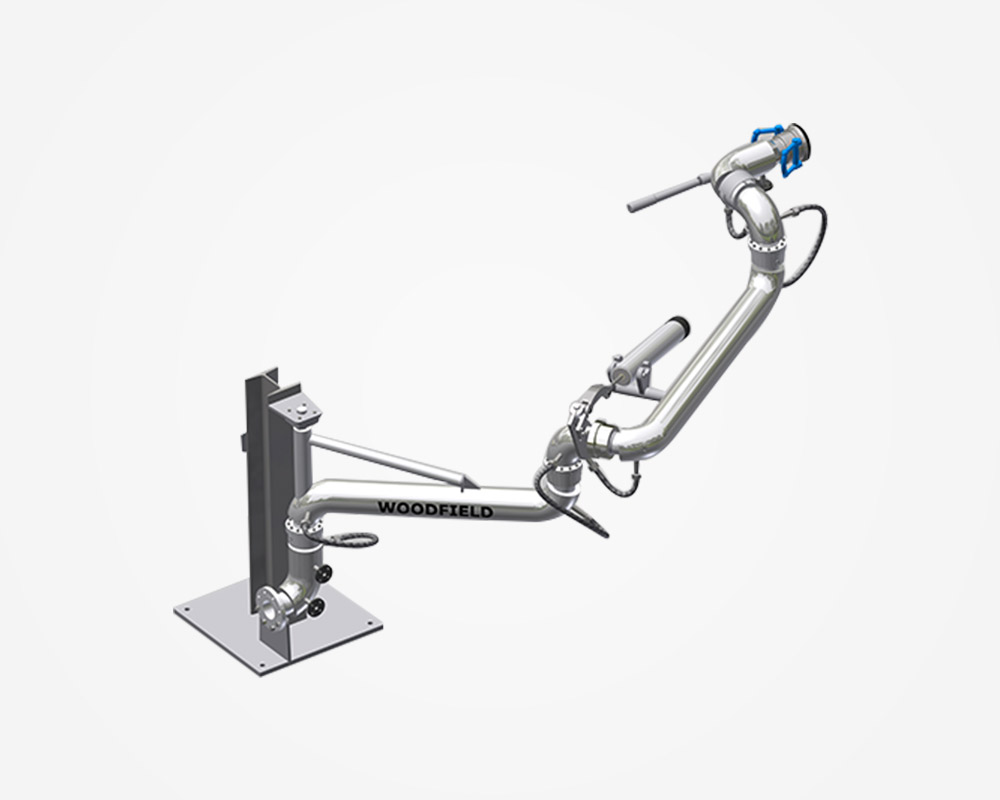

Jacketed Top

LOADING ARMS

Top loading of highly viscous material is most challenging. Products like Bitumen, Asphalt, Molten Sulphur, etc. are extremely tricky to handle. WSI's Jacketed top loading arms are ideal for such products that require minimal/no heat loss during transfer to tank trucks, rail cars, ISO container tanks and where signi cant miss-spotting is likely and additional equipment is carried by the loading arm.

- W440 PJ LONG REACH

W440 PJ LONG REACH

DETAILS

W440 PJ Steam Jacketed long reach top loading arms are ideal for industrial products that require minimal/no heat loss during transfer to tank trucks and rail cars, and where signi cant miss-spotting is likely and additional equipment is carried by the loading arm.

The W440-PJ’s longer reach and significant miss-spot capabilities are due to a “supported swivel boom” that extends from the riser on the stand post and to which a xed reach loading arm is attached. The supported boom allows for even longer range and/or superior weight carrying capacity necessary for carrying steam jacketing and insulation. The supported boom provides an extra plane of rotation and allows the loading arm to “track” a considerable distance along the centerline of the tank truck, rail car or ISO tank container. Multiple drop pipe options available.

AVAILABLE SIZES

3” x 2”, 4” x 3”, 6” x 4” and 8” x 6”

AVAILABLE CONFIGURATIONS

Left Hand or Right Hand

Up Feed or Down Feed

Side Feed all mounted on a stand post

FEATURES

- Materials of construction: Carbon steels, 304L and 316L stainless steel Exotic alloys for specialty applications where applicable: Duplex Stainless Steel, Super Duplex Stainless Steel, 904L Stainless Steel, etc.

- Seals in Viton™, Nitrile, EPDM, PTFE, Kalrez™ etc. to suit the application

- Typical range of vertical movement is +70° park position to -20° load position.

- Compression spring, counterweight, pneumatic or hydraulic balance control systems

- Typical “supported boom” length is 2,000mm, and typical range of primary length is 2,000mm to 2,800mm with a 1,500mm drop tube. All dimensions can be changed to suit each application.

- Alternative drop tube arrangements are available to suit the specific application

CONTACT

Locations

-

13641 Dublin Court Stafford,

Texas 77477 -

+1 (803) 272-6313

-

sales.usa@woodfieldsystems.com

-

Avda. San Francisco Javier, 9 Off. 11-29,

41018 Seville, Spain -

+34 955 300 424

-

sales.es@woodfieldsystems.com

-

Nitco Biz Park, Plot C-19, Road 16, Wagle

Estate, Thane(W) - 400604, Maharashtra, India. -

+91 22 67040000

-

sales@woodfieldsystems.com

-

Marine House, Tyler Way, Swalecliffe Whitstable,

Kent, CT5 2RS United Kingdom -

+44 1227 793351

-

sales@woodfieldsystemsltd.com

-

Acueducto de Guadalupe CDMX. C.P. 07279.

Alcaldía. Gustavo A. Madero.Mexico -

+52 55 5064 6561

-

sales.mx@woodfieldsystems.com

ilemus@woodfieldsystems.com.mx

-

Woodfield Systems FZ-LLC

Level 9, The H Office Tower,

One Sheikh Zayed Road

Dubai, UAE -

+971 4 372 1354